A long time ago, a large Afrormosia tree was felled in the forests of central or western Africa. Somehow (and I’d love to know the full story here), it was transported to the UK, presumably via a sawmill along this great journey, where it came to rest in Northamptonshire, as a solid bannister rail in a newly built shopping centre. Some years later, the shopping centre underwent a major refurb and the bannisters that had been assisting shoppers, along with a great deal of other previously rather expensive building materials, were condemned to live out their days, stocking the local land-fill site. Even back in the ‘days of plenty’ before recycling and cheaper substitute materials became a thing, Dad, who was working on the refurb project, recognised that these were ‘good bits of wood’ that could be re-used and should be kept. Certainly, as was his trademark catch phrase, they would probably ‘come in handy one day’. And so it was, that a lorry load of broken up stair bannisters, ended up in his possession. And they certainly did come in handy as he and Mom built and furnished their home.

Fast forward thirty years, and carefully stacked along the side of the garage, were the last remaining lengths of this now endangered species. As The Cottage required some new window sills, this fine, rare timber seemed like the perfect thing to use. All I had to do was cut, trim, plane, stick, smooth, sand and shape them and somewhere along the line, transport them to Wales. Like most of our expeditions and journeys, they only really become a reality after a lot of thinking, pondering and then talking about an idea we’ve had. The same was true for the wood. We’d literally been looking at it for years, wondering what to make with it! The time finally came, back in September, when Mother and I made the first big step into the depths of The Den.

In what can only be described as a ‘health and safety nightmare’ we got fully involved with the challenge of using the big table saw. Having (very sensibly), tried to get this part done at a joiners shop, we were turned away as they didn’t have a big enough saw and couldn’t take the safety guards off their table saw. Somewhat deflated, we returned to The Fort, to discover that there were no safety guards to remove on Dad’s gear – so psyched up with masks, goggles, ear plugs and revved up the beast! It was a nerve wracking affair ripping the thick planks through the huge circular blade that looked like something from a horror film. With great care, and in a blizzard of saw dust, we tore through the first few and after thinking we’d blown a fuse, kept the blade turning long enough to make the final cuts with all our fingers and limbs intact.

We were soaked in sweat and literally covered head to toe in dark saw dust. Tea on the terrace was required before we could load the new ‘thinner’ (yet still incredibly heavy) planks, back into the van and make our second trip to see ‘Jeremy the Joiner’. This time, he was able to use his big planer to even up our work and add in a small groove on the edges to help stick them together. We returned to the Den, to try and clear up the small mountain of saw dust that had accumulated in the door way.

With the wood looking smooth and grooved, it was loaded once again into the van and taken up to The Cottage. Rather than jump straight in, it seemed prudent to try a ‘test piece first, to check the technique for joining the lengths together. The walls of The Cottage are over half a metre think, so a window sill actually requires quite a lot of timber!

More cuts, big clamps, some glue and oak strips to make the tongue and groove joint, followed by a lot of sanding and it began to look like we might be ready to go for the big bits.

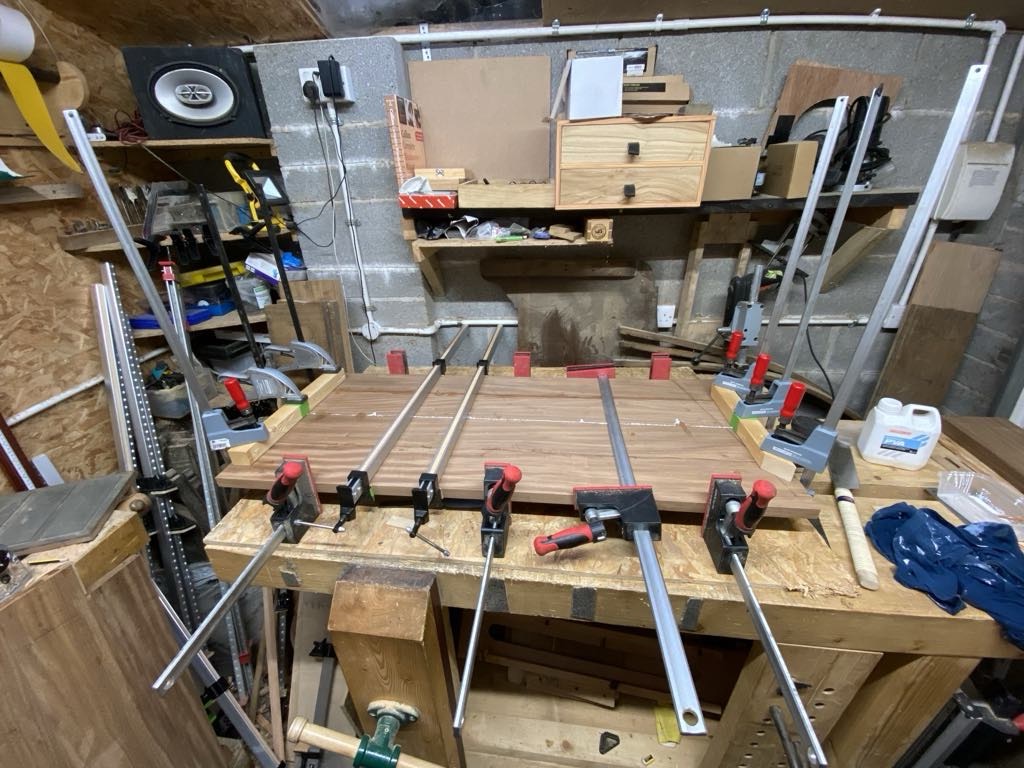

As it turned out, sticking together a couple of small lengths was a much easier operation than doing the same for a 1.5m length of wood. Up until now, my workshop had been in the back of the van, so I enlisted the help of Matt and his workshop. It soon became clear that Dad’s two large sash clamps were going to be woefully inadequate. Luckily there seemed to be no shortage of supply at Matt’s place. At one point there were twelve clamps holding it all together and flat!

With the wood now stuck together as boards, there was the small matter of planeing them smooth, using a small metal sheet, to scrape away the excess glue and level things up. A incredibly addictive experience and painfully fatiguing on the thumbs, but, as promised, it did give a good looking surface.

Cutting the boards to the correct shape then became the next project and having taken so much time and effort to get this far, it was with some trepidation that I measured and re-measured about hundred times. I took Howard and Matt’s advice and made a template from some cardboard, as none of the walls are straight or involve an right angle.

With the loan of a delicate saw and after an evening spent practicing with Matt in his workshop, I tentatively made the detailed cuts….

Before bringing out the big guns to ensure that there were some actual straight edges!

The saw on the runner was a thing of beauty and made an unbelievably perfect cut along the edges,

All that was left was to oil and wax them up and get them inside The Cottage – the big question was ‘would they fit!?’.

The one in the snug, had to go in and out a few times for some micro adjustments, but there was a huge sigh of relief (followed by a cheer!), when the lounge one slotted perfectly into the gap!

For a bit of wood that’s been stored, moved, stored, moved and kept safe for years, ready to ‘come in handy’, it felt great to see it slotting into a bit of The Cottage.

Leave a reply to Anonymous Cancel reply